Our Facilities

Our two production facilities are located in the Conghua Economic Development zone, approximately one hour drive from downtown Guangzhou.

production FACILITY STANDARDS

Our facilities are inspected and audited each year by leading international companies. We employ over 300 full-time staff and strictly comply with all governmental labour laws. Each of our employees are provided with regulatory benefits and participate in our bonus scheme incentives. Each and every one of our staff is highly valued and we have strived over the years to achieve a family-like atmosphere across each of our sites.

STANDARD PRODUCTS DIVISION

Constructed in 2010, our Standard Products division's primary focus is to develop and manufacture material handling products for the Chinese domestic industrial market. Such products include plastic pallets, crates, totes, boxes and a limited number of traditional plastic homeware products. In addition, the division produces small parts for the Cooler division.

We have developed, maintain and own more than 200 moulds that are used to produce our Rodman™ range and supply OEM brands.

Our in-house sales team distribute products via B2B and wholesalers throughout China.

FACT SHEET

AREA

Workshop Area: 3,672 sq. m.

Assembly Area: 1,170 sq. m.

Warehouse Area: 5,592 sq. m.

Administration Area: 1,350 sq. m

Material Handling Area: 2,500 sq.m

Loading Area: 3,763 sq. m.

Total Area: 18,047 sqm

MACHINERY

17 x Injection Mould Machines

1 x Extrusion Machine

PRODUCT PRINTING

1 x Hot Stamp Machine

CERTIFICATIONS

ISO9001:2000

GB/T 19001-2000

COOLER DIVISION

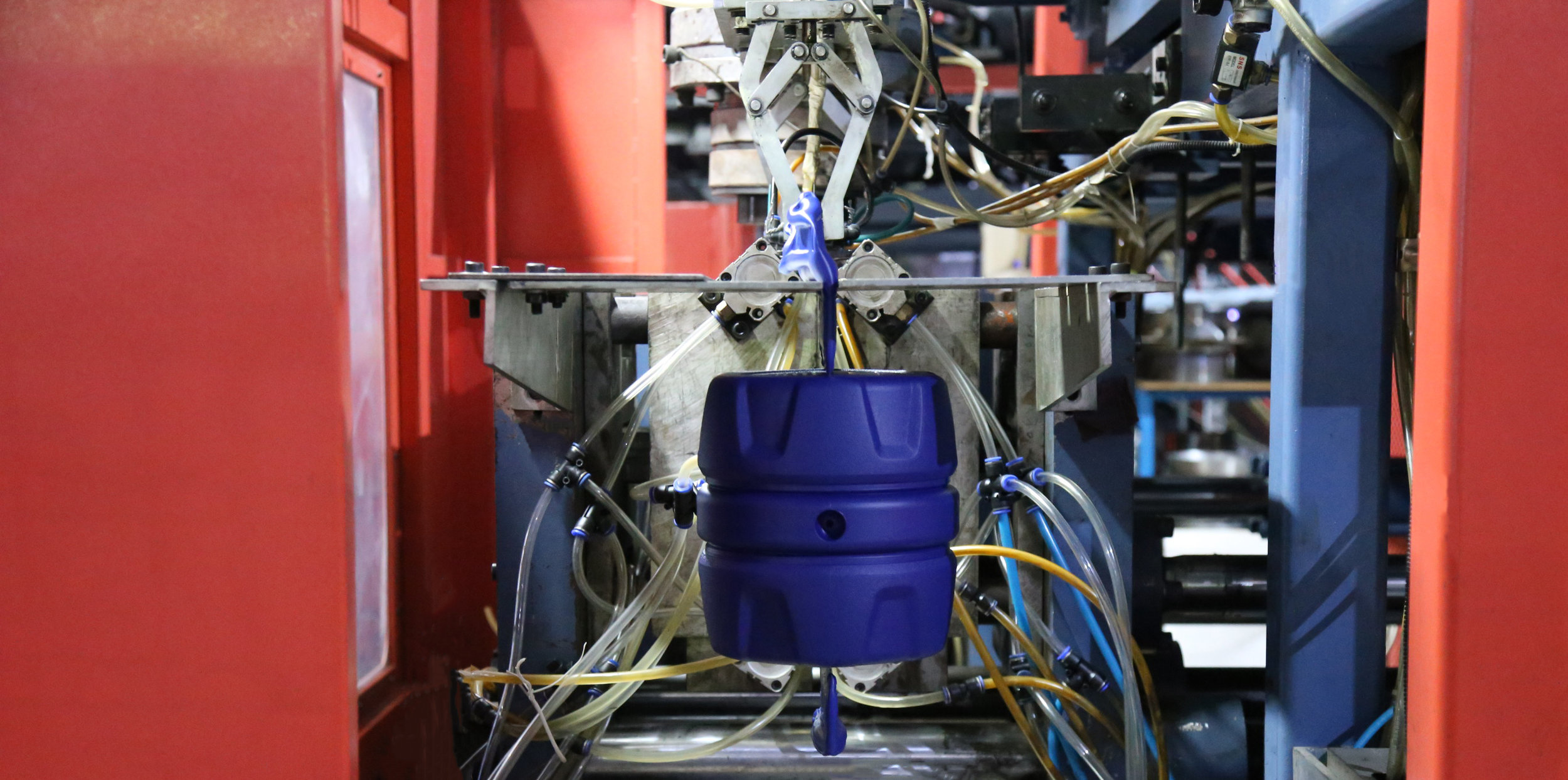

Built in 2013, our Cooler Division is dedicated to manufacturing both domestic and commercial coolers for our international and local customers. Our blow moulding machines produce coolers ranging in size from 2 litres to 150 litres. All cooler inners and lids are made with food-grade raw materials and comply with US FDA food safety standards and requirements.

We have developed, maintain and own 65 precision moulds and over 120 custom-built jigs used in the PU foaming process.

Our sales team distribute our coolers directly, through our wholesale network and online via JD.com.

FACT SHEET

AREA

Workshop Area: 1,547 sq. m.

Assembly Area: 1,944 sqm

Warehouse Area: 2,382 sqm

Administration Area: 438 sqm

Total Area: 6,311 sqm

MACHINERY

6 x Injection Moulding Machines

3 x Blow Moulding Machines

3 x Hot & Cold Gel Line Packaging Machines

PU FOAMING

2 x PU Foaming Machines

2 x Carousels

PRODUCT PRINTING

2 x Heat Transfer Machine

1 x Screen Printing Machine

1 x Hot Stamp

CERTIFICATIONS

ISO9001:2000

GB/T 19001-2000